Kvalitet er livet til vårt merke

Horsent Kvalitetsavdeling er ansvarlig for verifisering, identifisering og sporbarhet av produkter før levering, deltar i kontroll og bekreftelse av produksjons- og tjenesteytelsesprosessen for berøringsskjermer, og organiserer tilsyn, inspeksjon, overvåking og måling av organisasjonen og produksjonsprosessen. , som har den absolutte makten over produksjonsavdelingen til å begrense produktets utgående og nekte prosessen i produksjonsflyten når det er nødvendig for å stoppe NG-produktstrømmen til neste stopp, selv kundenes hånd.Frigjør deg fra risikoen for kvalitet og uendelig reparasjonsarbeid, pluss å bygge et godt kundemerkeomdømme.

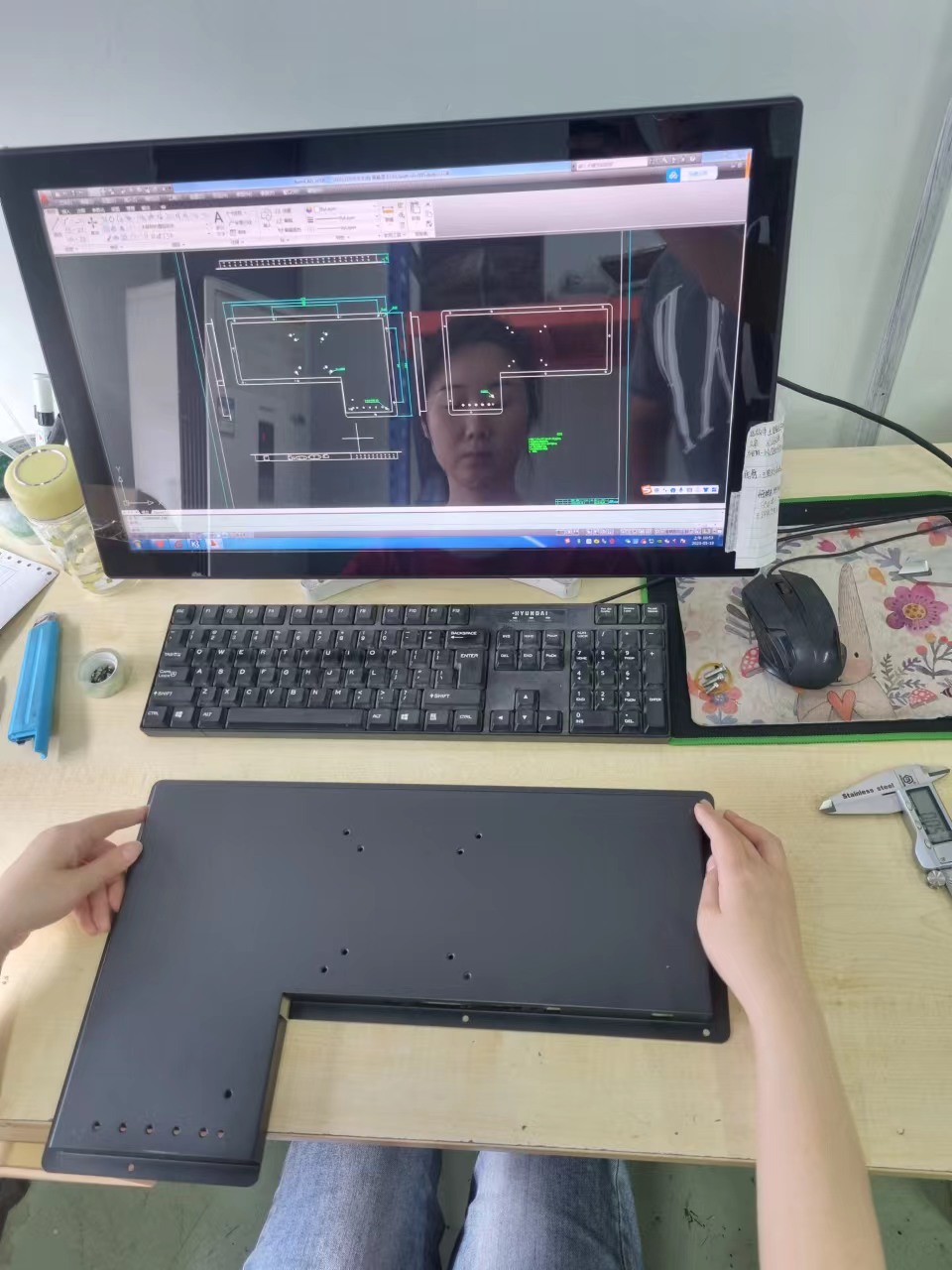

Horsent gjennomfører strenge kvalitetskontroller både funksjonskontroller og visuelle inspeksjoner

for LCD-er 100 %, inkludert farger, lysstyrke, lyse og døde punkter, reaksjonstider, oppløsninger...

for bolig- og konstruksjonsdeler.Vi inspiserer synlig farge, form, dimensjon, riper...

PCB: både funksjoner og synsinspeksjoner på layout, linjer og komponenter.

Horsent sjekk 100% våre utgående produkter i følgende inspeksjonsliste:

Monitor Display, og visuelle inspeksjoner på hus, glass og profiler, hjørner.

Berøringsskjermfunksjoner, punkter og reaksjoner.alt-i-ett funksjonstest.